Brief Introduction

Leakage has become one of the most common diseases among a large number of reservoirs and dams. Leakage not only affects the power generation, water supply and irrigation efficiency of the reservoirs, but even directly threatens the safety of the project. Effective and accurate detection of leakage is an important prerequisite for dam safety evaluation and reinforcement treatment. Due to the large scale, wide range and complex anti-seepage system of dam buildings, the leakage has the characteristics of large water depth, dispersed distribution and small flow rate, and has strong complexity and concealment. Because, it is difficult to empty the large dams, or the empty reservoir will bring great environmental impact and economic cost, underwater detection of hidden leakage hazards of large dams is a technical problem that needs to be solved urgently in the field of dam safety. During years of research and practice, Changjiang Design Group Co., Ltd. has developed video and sonar integrated deepwater leakage detection technology and equipment to overcome the difficulties of large water depth, complex operating environment and high operating risks in dam leakage detection. This technology has the advantages of short implementation period, low security risk, high reliability, and good economy.

In 2023, the technical team of Changjiang Design Group Co., Ltd. applied this technology to go abroad and serve the dam safety of the Belt and Road. The maximum height of the dam of Cambodia E Hydropower Station is 125m. The dam was opened for water storage in May 2013, and the leakage of the dam at the normal water level is about 300L/s. Figure 1 shows the current photograph of the water gauging weir behind the dam. In order to find out the leakage of the dam, the technical team adopted the video and sonar integrated deepwater leakage detection technology for underwater detection. The water depth at the time of detection was about 110m.The detection steps are as follows:

Based on the analysis of seepage monitoring data, key detection areas and possible leakage parts are determined.

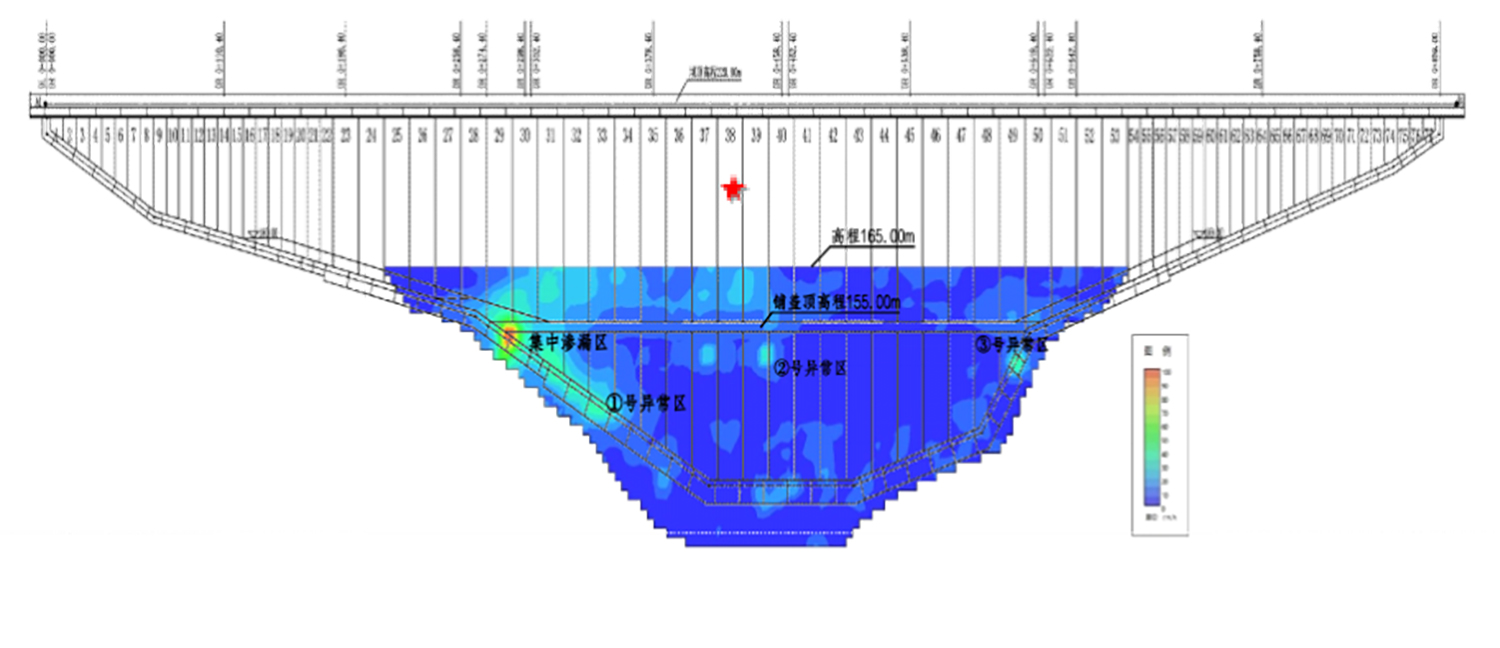

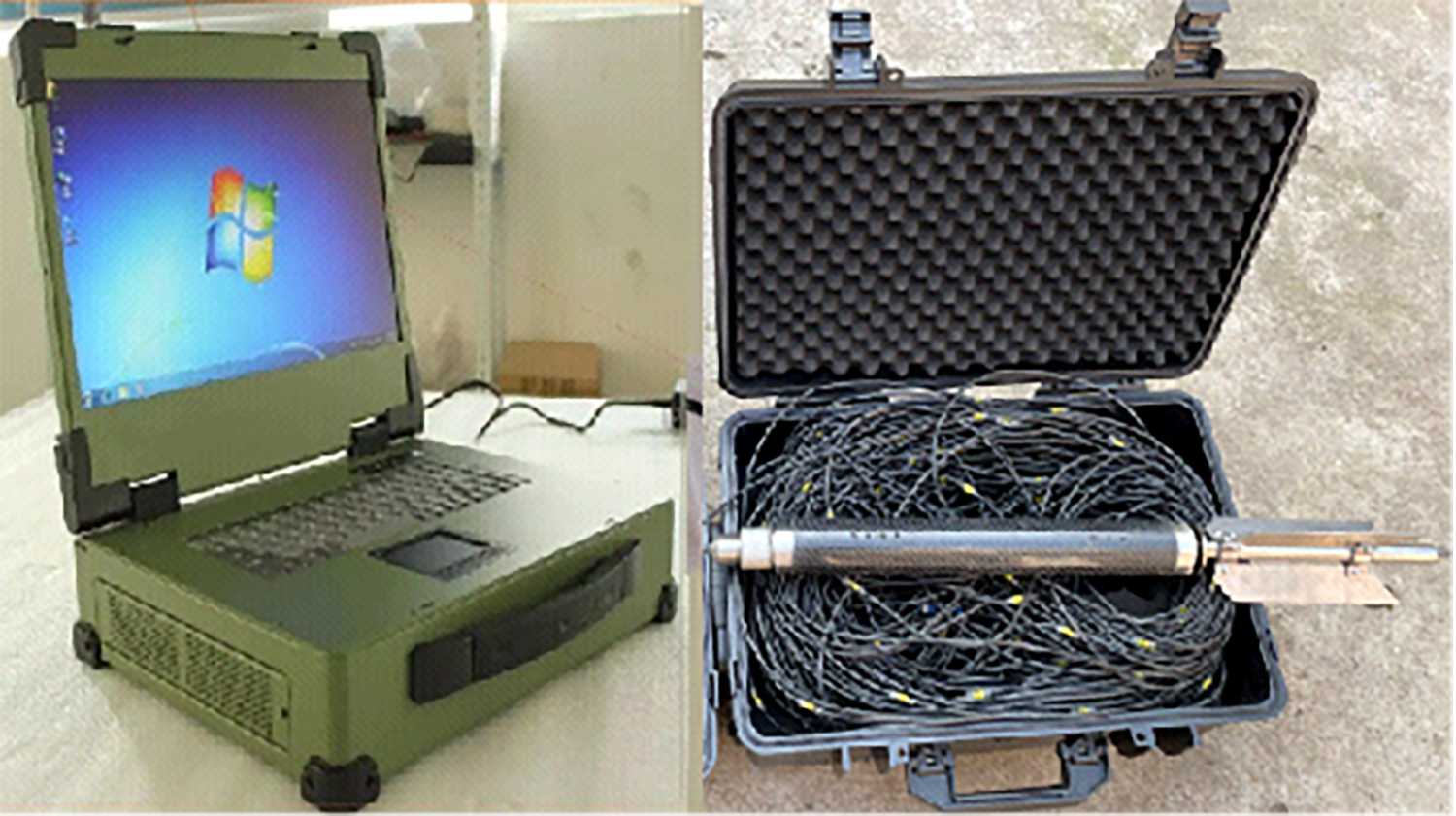

Divide the detection area grid, set up measuring line, and encrypt the grid of key detection area and possible leakage part. Utilize the excellent conduction characteristics of sound wave in water and Doppler principle, and adopt the leakage sonar detection method to carry out wide area survey (Figure 2). By judging whether the flow velocity of water in the detection area and adjacent area is abnormal or not, the leakage abnormal area is determined. See Figure 3 for the leakage sonar detection equipment. The detection efficiency of this method is not less than 1000m2/day; the detection accuracy can reach 10-3cm/s level, 100 times higher than the existing technology; the detection depth is more than 100m. The leakage flow velocity distribution diagram (Figure 4), three-dimensional flow field distribution and other results can be output to visually display the leakage area.

The self-developed "deepwater leakage high-definition tracing detection platform system" (Figure 5) integrates high-definition camera, image sonar, tracing system, lighting, laser width finder and other detection equipment to conduct detailed inspection of abnormal areas found by sonar detection, and carry out tracing inspection to find out the defect form and leakage degree, so as to realize dynamic real-time analysis and judgment of underwater leakage areas. The leakage defect positioning accuracy reaches m level.

The leakage location of the Cambodia E dam panel leakage prevention system was identified, and after leakage treatment, the leakage amount of the dam was significantly reduced.

The technology has been appraised as "reaching the international leading level" in the field of reservoir and dam leak detection. It has won the first prize of Hubei Provincial Science and Technology Progress Award, the special prize of China Dam Engineering Society for Science and Technology Progress Award, and the first prize of hydropower science and technology award. It has obtained 3 authorized invention patents, 17 utility model patents, 3 computer software copyrights, 2 supporting industry standards, 3 published academic monographs in related fields, and more than 20 published academic papers in related fields. It has been applied in more than 30 large and medium-sized reservoirs in China, such as Hunan Baiyun Reservoir, Chongqing Leye Reservoir, Yunnan Puxiqiao Hydropower Station, Guangxi Dateng Gorge cofferdam, a panel dam in Xinjiang, and T and E hydropower stations abroad. It has broad prospects for promotion and application and has huge economic and social value.

In 2023, the technical team of Changjiang Design Group Co., Ltd. applied this technology to go abroad and serve the dam safety of the Belt and Road. The maximum height of the dam of Cambodia E Hydropower Station is 125m. The dam was opened for water storage in May 2013, and the leakage of the dam at the normal water level is about 300L/s. Figure 1 shows the current photograph of the water gauging weir behind the dam. In order to find out the leakage of the dam, the technical team adopted the video and sonar integrated deepwater leakage detection technology for underwater detection. The water depth at the time of detection was about 110m.The detection steps are as follows:

Based on the analysis of seepage monitoring data, key detection areas and possible leakage parts are determined.

Divide the detection area grid, set up measuring line, and encrypt the grid of key detection area and possible leakage part. Utilize the excellent conduction characteristics of sound wave in water and Doppler principle, and adopt the leakage sonar detection method to carry out wide area survey (Figure 2). By judging whether the flow velocity of water in the detection area and adjacent area is abnormal or not, the leakage abnormal area is determined. See Figure 3 for the leakage sonar detection equipment. The detection efficiency of this method is not less than 1000m2/day; the detection accuracy can reach 10-3cm/s level, 100 times higher than the existing technology; the detection depth is more than 100m. The leakage flow velocity distribution diagram (Figure 4), three-dimensional flow field distribution and other results can be output to visually display the leakage area.

The self-developed "deepwater leakage high-definition tracing detection platform system" (Figure 5) integrates high-definition camera, image sonar, tracing system, lighting, laser width finder and other detection equipment to conduct detailed inspection of abnormal areas found by sonar detection, and carry out tracing inspection to find out the defect form and leakage degree, so as to realize dynamic real-time analysis and judgment of underwater leakage areas. The leakage defect positioning accuracy reaches m level.

The leakage location of the Cambodia E dam panel leakage prevention system was identified, and after leakage treatment, the leakage amount of the dam was significantly reduced.

The technology has been appraised as "reaching the international leading level" in the field of reservoir and dam leak detection. It has won the first prize of Hubei Provincial Science and Technology Progress Award, the special prize of China Dam Engineering Society for Science and Technology Progress Award, and the first prize of hydropower science and technology award. It has obtained 3 authorized invention patents, 17 utility model patents, 3 computer software copyrights, 2 supporting industry standards, 3 published academic monographs in related fields, and more than 20 published academic papers in related fields. It has been applied in more than 30 large and medium-sized reservoirs in China, such as Hunan Baiyun Reservoir, Chongqing Leye Reservoir, Yunnan Puxiqiao Hydropower Station, Guangxi Dateng Gorge cofferdam, a panel dam in Xinjiang, and T and E hydropower stations abroad. It has broad prospects for promotion and application and has huge economic and social value.